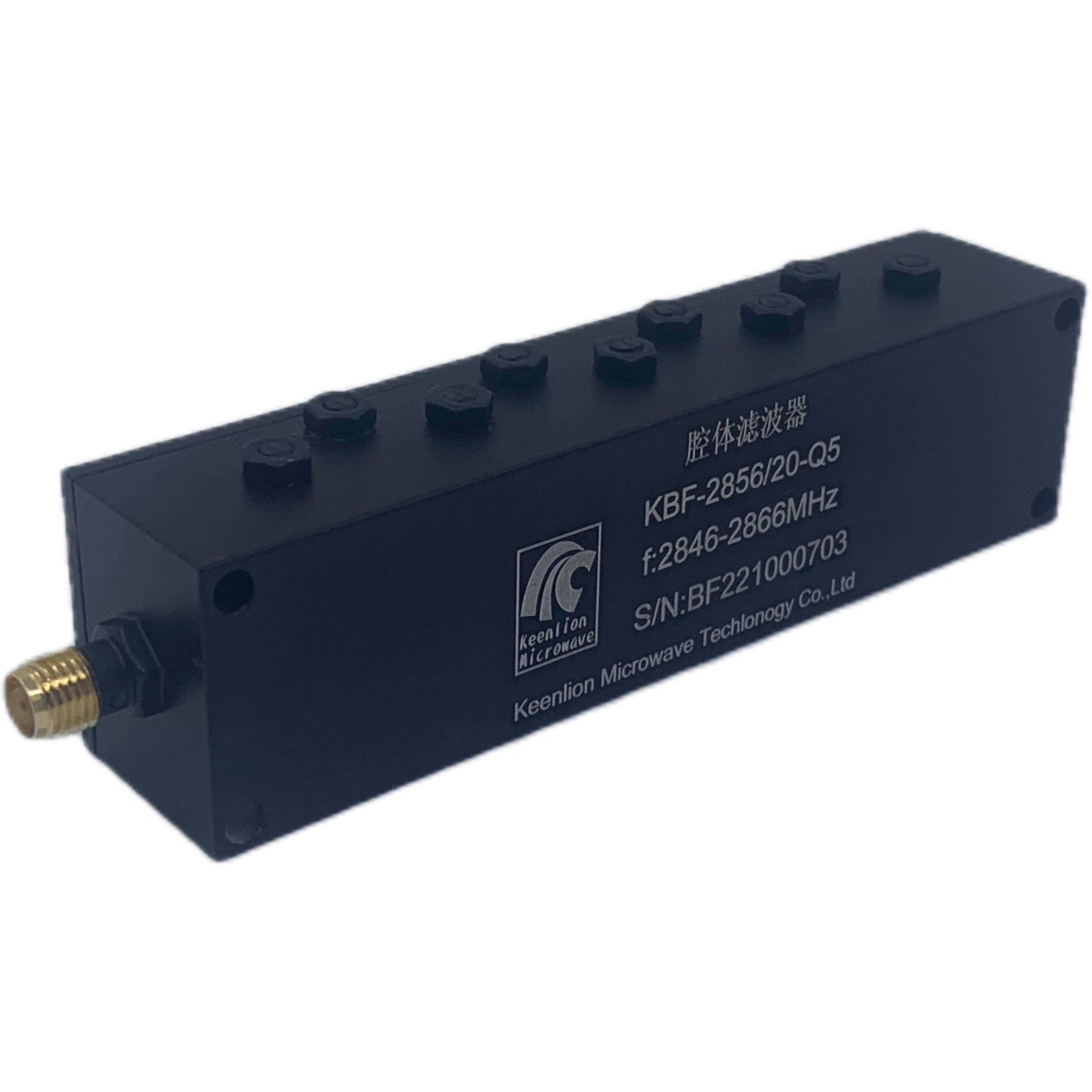

Customized RF Cavity Filter 2856MHz Band Pass Filter

The Cavity Filter blocks 2846-2866MHZ frequency range and rf fliter with high attenuation.Keenlion stands as a trusted source for high-quality, customizable 2846-2866MHZ Cavity Filter. Our steadfast commitment to excellence, customization, direct communication approach, competitive pricing, provision of samples, and timely delivery ensures that our customers receive top-tier products and service.

Main Indicators

| Product Name | Cavity Filter |

| Center Frequency | 2856MHz |

| Bandwidth | 20MHz |

| Insertion Loss | ≤1dB @ F0 ± 5MHz ≤2dB @ F0 ± 10MHz |

| Ripple | ≤1dB |

| Return Loss | ≥18dB |

| Rejection | ≥40dB @ F0 ± 100MHz |

| Port Connectors | SMA-Female |

Outline Drawing

Company Profile

Cost-Effective Pricing

Sichuan Keenlion Microwave Technology is a leading provider of high-performance microwave components and services for microwave applications worldwide. Our cost-effective products include a wide range of power dividers, directional couplers, filters, combiners, duplexers, customized passive components, isolators, and circulators that are designed for extreme environments and temperatures. Our products are available in various specifications, tailored to meet the specific requirements of our clients, and are suitable for all standard and popular frequency ranges, with bandwidths ranging from DC to 50GHz.

Strict Assembly Process

Our manufacturing process follows the highest standards to ensure the quality and reliability of our products. Our strict assembly process adheres to all the necessary requirements like installing the smaller parts before the larger ones, internal installation before external installation, lower before higher installation, and pre-installation of fragile components to avoid any damage. Our manufacturing process prioritizes ensuring that one production process does not negatively impact the subsequent ones.

Quality and Capabilities

We prioritize quality control and understand the importance of meeting the specifications provided by our clients. Our professional inspection team conducts testing after product debugging to ensure that all the quality requirements are met before packaging and shipping them to our clients.

Manufactured by Keenlion

Sichuan Keenlion Microwave Technology is dedicated to providing high-quality and cost-effective microwave components and services. We take pride in our strict adherence to manufacturing procedures, quality control, and customization options. Our flexible manufacturing capabilities allow us to produce components that are tailored to each client's specific needs, making us an ideal partner for all your microwave component needs.